Our reliable set of standards drives predictable, consistent outcomes across the country

Operations playbook

By builders, for builders

Informed by more than four decades of building, we’ve built a repeatable, scalable playbook to power the Suffolk System. Our large national portfolio means we can quickly figure out what works and tailor our processes by sector and market. Then, through our Mission Control hub, we can monitor, direct and support a project from start to finish.

An approach you can trust

We know that proper preconstruction and startup determine a project’s success. To kick off the job right, we hold several assessments and reviews with the project team, peers and leadership, bringing to bear the collective experience of our builders.

Our data analytics team has found that the safety observations project teams make in the field, along with site supervision, have a direct correlation to safety performance. So, we’ve made observations and staffing ratios key to our safety approach.

Backed by data and based on Suffolk’s historical performance, Schedule 9 Box is an integral tool in our schedule review process throughout the project lifecycle. We’ve tailored this tool for a range of sectors and building types.

We manage quality by emphasizing consistency, continuous improvement, and a zero-defect culture where our teams identify and correct deficiencies throughout construction to reach our goal of a zero-defect punchlist.

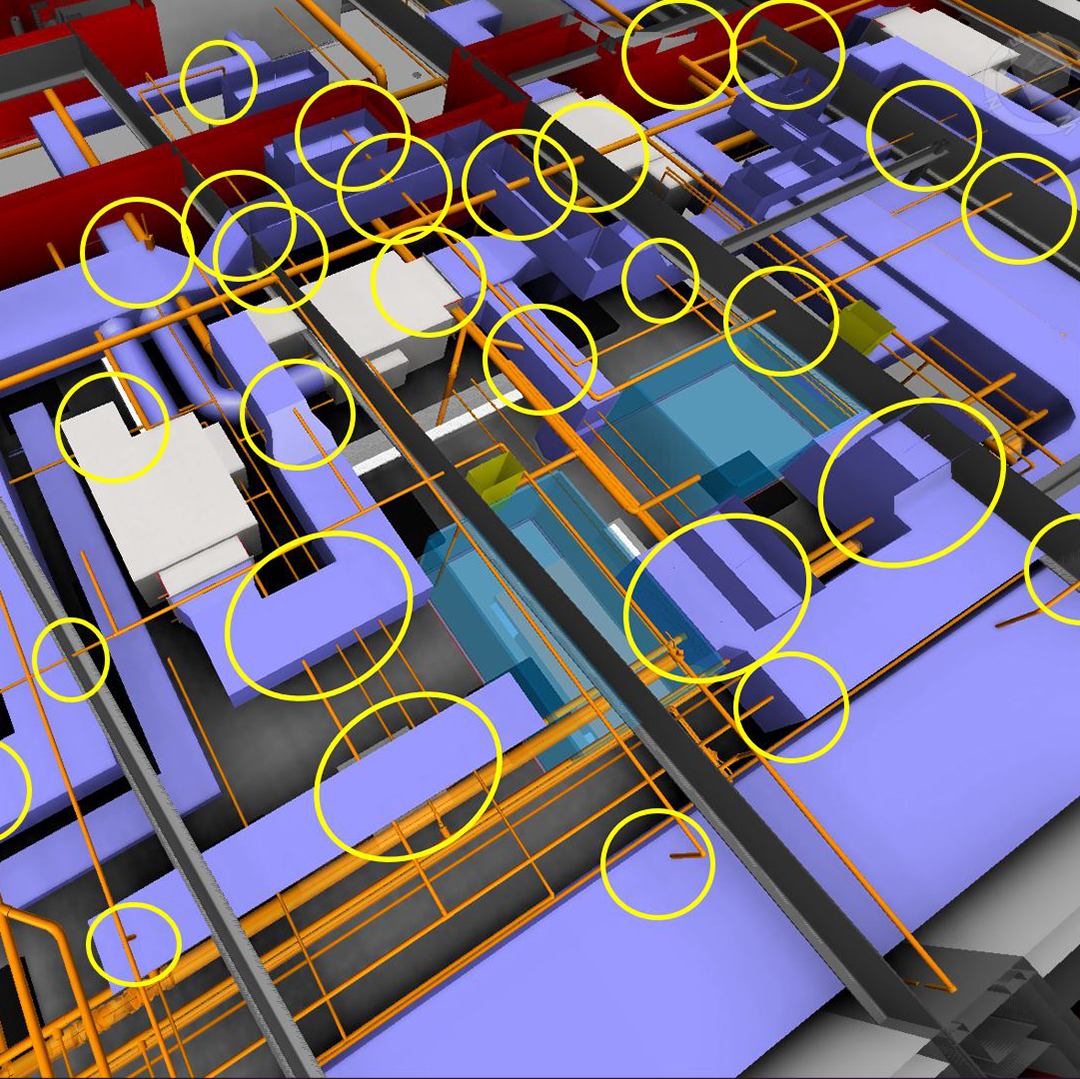

At Suffolk, we build projects digitally before we build them physically. Our Digital Engineering team collaborates with design teams and trade partners to develop BIM models that detect issues and pave the way for a better construction experience.